About Carter Arris Portfolio

My Education

My Experience

My Education

I am a recent graduate with a Bachelor's Degree in Mechanical Engineering with a side emphasis of applied mathematics. I graduated Summa Cum Laude with a GPA of 3.72. I am a Bay Area native, and am looking to work full time in a Mechanical Engineering related field.

My Skills

My Experience

My Education

I have extensive experience with rapid prototyping, testing and designing. Utilizing a variety of skills from CAD and FEA to C programming and MATLAB, I am confident in my ability to tackle engineering problems.

My Experience

My Experience

My Experience

I have worked the past three summers at Neptune Medical, starting out in their Cardio Vascular team, working on dynamic rigidization. Transferring to their Robotics division for my third summer, I worked on flexible robotic endoscopy and its manufacture.

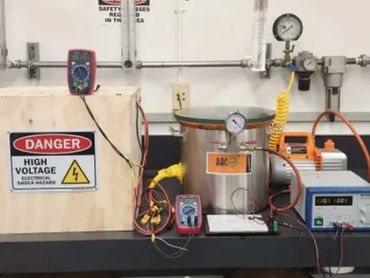

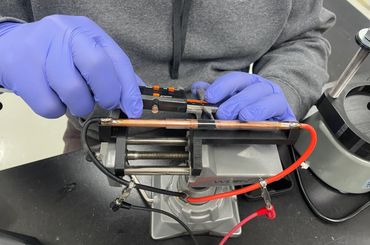

Flash Joule Graphene Synthesis System

The Flash Joule Graphene Synthesis System was my senior project and the culmination of all my learning at University of the Pacific. This project won the award for the best senior project. The project consisted of increasing throughput, enhancing safety measures, and adding user-friendly features to the Rice University Flash Graphene synthesis process. This was accomplished in a three strep process.

Pre-Processing:

The Post Processing stage consisted of prepping carbon samples to be turned into graphene. This was accomplished by controlling mass and resistance.

Flash Graphene Synthesis:

The prepared samples were then connected to a electronic circuit, where it acted as a resistor. A large amount of energy determined by the set mass is released through a capacitor bank, which superheats the carbon sample. Cooling occurs immediately and quickly via radiation. Such fast heating and cooling prevents the layers of what would be graphite from sticking to each other, producing graphene.

Post-Processing:

A combination of carbon, graphite, and graphene are produced in this process, all of which remain in a powder form. A sieve stack is utilized with variable frequencies to allow the powders to flow and separate by grain size.

Experimental Drag Measurement

Overview

The purpose of this experiment was to compare theoretical and experimental drag for

different angles of attack on a standardized NACA-0009 airfoil that had been scaled

to 10%. The project was able to accurately take measurements for varying angles of

attack compare the data to what was expected theoretically.

Setup

Airfoils at varying angles of attack were 3D printed and installed into a wind tunnel in

order to simulate different fluid velocities. A pitot tube and Bernoulli's equation was used

to determine fluid velocity, and a hinged lever and scale was used to determine drag.

Results

Through the data that was found experimentally, we were able to calculate both

Drag Coefficient and Reynolds number for varying angles of attack. The data

was plotted against each other and trends that matched our expected results

were found.

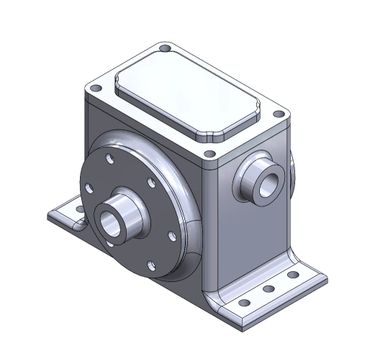

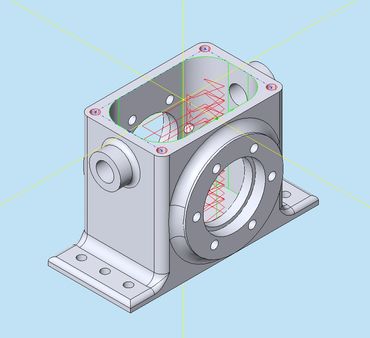

Worm Gear Transmission System Design and CNC Fabrication

Overview

The Worm Gear Transmission project consisted of recreating existing gearbox and modifying it to be manufactured using a 3 axis CNC machine. The design was created in Solidworks using measurements taking from a physical model, which was then modified in order to be manufactured with certain constraints. The final model was examined using a digital CMM and had surface exceptional tolerances.

.jpg/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:370,cg:true)

Contact Me

Questions or Comments

Please feel free to reach out to me if you have any questions.

Mobile: (650) 787-1131

Email: arriscarter2001@gmail.com

LinkedIn: Click Here

Copyright © 2024 Carter Arris Portfolio - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.